Strengthening “Safety Barrier” of Stator Winding Temperature: NTC Temperature Sensor in Action

The rotating magnetic field generated by the stator winding will prompt the rotor to rotate, converting electrical energy into mechanical energy and assisting the motor in providing power for new energy vehicle. Since the stator winding generates heat when current flows through it and the magnetic field changes, excessive temperature can lead to a decrease in the performance of the drive motor or even damage. Therefore, it is necessary to installed NTC temperature sensor to monitor temperature changes and ensure the stable operation of the stator winding.

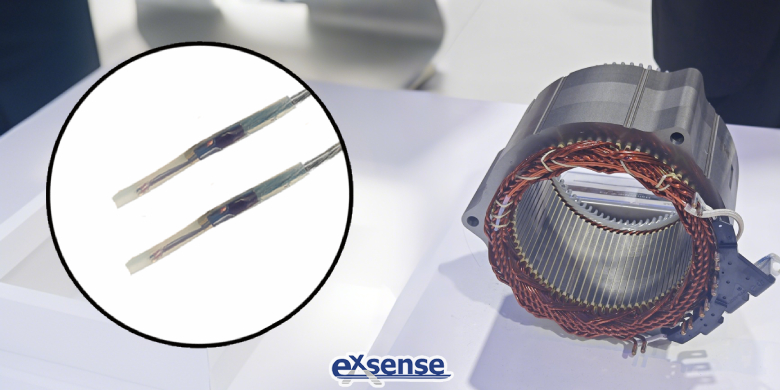

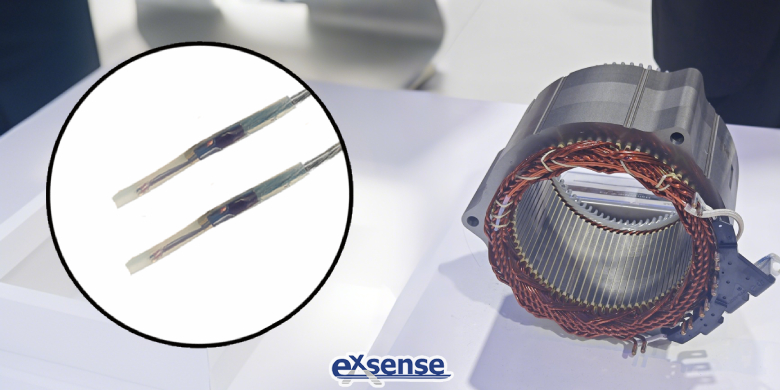

NTC temperature sensor is typically installed in the stator winding slots or at the ends for real-time temperature monitoring. When the driver starts the vehicle, the NTC temperature sensor immediately begins monitoring the temperature changes of the stator winding. Once temperature information is generated, the NTC will transmit it to the controller. When the drive motor temperature exceeds a preset threshold, the controller will quickly trigger protective mechanisms, such as reducing power output or limiting torque, effectively preventing issues such as insulation failure and demagnetization of the magnetic core caused by overheating of the drive motor, ensuring its stable operation and extending service life.

In this process, the highly reliable NTC temperature sensor from EXSENSE Electronics, with its rapid response, can assist the stator winding in capturing transient temperature changes promptly under complex working conditions. Furthermore, the high accuracy of the NTC temperature sensor can effectively enhance the accuracy of temperature monitoring of the stator winding and reduce errors in obtaining temperature data. Additionally, the NTC temperature sensor produced by EXSENSE can withstand temperatures up to 180℃, ensuring that the stator winding maintains excellent working conditions even in high-temperature operating environments in new energy vehicle. As a “safety barrier” for the stator winding temperature, the NTC temperature sensor always remains “vigilant” to safeguard it:

1. Monitoring the stator winding junction temperature to ensure efficient operation of the drive motor

The resistance value of the NTC temperature sensor decreases exponentially with increasing temperature, allowing it to detect slight temperature fluctuations. During the operation of the drive motor, temperature changes of the stator winding can significantly affect its performance. By inserting NTC temperature sensor, real-time monitoring of the stator winding temperature changes can prevent overheating hazards and reduce the risk of drive motor failure.

2. Adapting to a wide temperature range to ensure reliability of drive motor

The NTC temperature sensor for stator winding have a wide temperature tolerance range, capable of accurately measuring temperatures even in winter, providing data support for pre-heating and starting control of the drive motor. Additionally, during summer or prolonged high-temperature operation of the drive motor, the NTC temperature sensor can also stably measure temperature, ensuring that the drive motor's working state will not be affected due to changes in environmental temperature.

The NTC temperature sensor for stator winding produced by EXSENSE Electronics is a key component for the safe and stable operation of the drive motor, helping the stator winding achieve precise intervention before reaching the critical point of thermal runaway of the drive motor. The addition of NTC temperature sensor for stator winding upgrades the safety of drive motor operation from passive defense to proactive prevention, enhancing performance while reducing the risk of failure.