Thermal management of SiC Silicon Carbide Module, NTC Thermistor is on High Alert

As one of the core components of new energy vehicle, the reliability of SiC silicon carbide module is directly related to the life and performance of the equipment. With the increase of power density and operating frequency, the temperature rise of silicon carbide module is becoming more and more prominent. As an electronic component that is sensitive to temperature changes, NTC thermistor has become the first choice for temperature monitoring of silicon carbide module.

When the silicon carbide module is working, the current passing through will generate heat, and if the temperature is too high, the performance of the module may be reduced, the life will be shortened or even damaged, affecting its normal operation. In order to avoid these problems, NTC thermistor needs to be used to cooperate with the internal devices of the silicon carbide module to monitor the temperature changes of the module in real time to ensure that the module operates within the normal temperature range:

1. When the junction temperature of the silicon carbide module increases, the resistance of the NTC thermistor decreases, and the change in resistance value can be converted into a voltage or current signal through the circuit connected to it. This signal can reflect the temperature status of the silicon carbide module and provide accurate data support for module temperature monitoring. In the SiC module, the NTC thermistor is mounted in the vicinity of the SiC chip and senses its temperature in real time. Once the temperature rises/drops abnormally, the resistance value of the NTC thermistor decreases/increases, and the voltage signal in the circuit changes, and the control unit of the silicon carbide module can take timely protection measures according to this signal to ensure the stable operation of the module.

2. Generally, the NTC thermistor in the silicon carbide module will form an over-temperature protection circuit with the comparator and other components. When the temperature of the silicon carbide module rises abnormally due to overload, poor heat dissipation, etc., the resistance of the NTC decreases sharply, causing a significant change in the voltage or current in the circuit. The comparator compares the changed signal with the preset threshold. When the threshold is exceeded, the comparator outputs a trigger signal, and the control unit immediately takes corresponding protective measures after receiving the signal, such as reducing the on-time of the module, thereby limiting the current and reducing its heat generation.

In summary, NTC thermistor provides a reliable source of data for temperature monitoring of silicon carbide modules with its rapid response to temperature changes. In addition, the over-temperature protection function of the thermistor effectively ensures the safety of the module and prevents it from being damaged due to overheating, thereby improving the reliability and stability of the whole system.

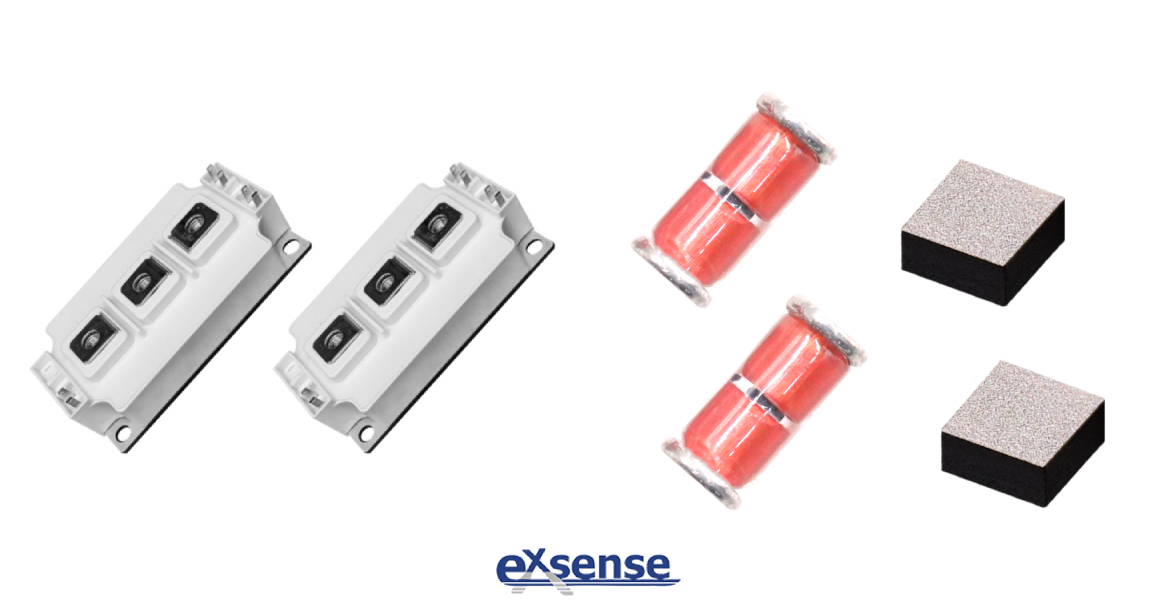

At present, most of the silicon carbide module solutions will use the GT-T series MELF glass encapsulated NTC thermistor from EXSENSE Electronics. Because it is a glass encapsulated structure, it can withstand the long-term high-temperature working environment of silicon carbide module. Moreover, this thermistor is a leadless NTC element, which is convenient for manufacturers to carry out SMT automatic assembly. With the continuous development of silicon carbide module process technology, EXSENSE Electronics has independently developed and delivered in batches the DT series solderable excellent-reliability NTC chip in order to cooperate with various automakers to product upgrade. Compared with the MELF glass encapsulated NTC thermistor, this NTC chip:

1. The accuracy can reach ±0.5%, which assists the silicon carbide module to carry out more accurate temperature monitoring and control;

2. The surface of the semiconductor ceramic adopts the densified process, which can withstand the acidic/reducing atmosphere in the packaging process of silicon carbide module;

3. The structure of the bare chip has a faster temperature sensing speed, and effectively avoids the failure caused by cracking of the glass shell of the MELF glass encapsulated NTC thermistor.