At present, the development trend of the driver is highly integrated, which can reduce the size of the driver, and more closely integrated with the IGBT module, making it easier to install, reduce the length of the cable between the driver and IGBT module, reduce the inductance of the lead. In order to achieve this goal, at present many well-known foreign enterprises have developed IGBT drive modules adopting their independent researched and developed ASIC (Application Specific Integrated Circuit). Through the application of ASIC, most of the control and protection functions can be realized by IC, which greatly reduces the size of the driver and increases the reliability of IGBT driver.

In terms of interface mode of IGBT user, in order to adapt to IGBT modules encapsulated by different manufacturers, IGBT drivers must have friendly user interface, extensive flexibility and reasonable economic cost. At present, the common drive module in the market is mainly welded to the PCB board, in order to better realize the connection with IGBT.

Since the drive module only provides the most important common functions in the driver, its connection with different modules in different applications needs to be completed by the interface board. The entire module - drive unit consists of a power module with a spring interface, a standard or enhanced drive core, and interface boards connecting the drive core to the specified module. An outstanding advantage of the customizable interface board is that users can adjust and determine the switching characteristics of IGBT. For example, adjust Rgon (Rg+) or Rgoff (Rg-) to change the speed at which IGBT is turned on or off; Adjust dead zone time or disable interlocking; Adjust the protection point and window time of saturation voltage (Vce). Compared with the intelligent power module IPM on the market at present, the interface board makes the whole system more flexible and easier to adapt to different applications. Once the system parameters are set, the whole system can be used as easily as IPM.

The short circuit or overcurrent protection and threshold regulation of IGBT are generally realized by detecting saturation voltage. When IGBT is short-circuited or overcurrent, its working area will exit from the saturation area and increase the saturation voltage. Undersaturation detection of IGBT is realized by connecting the diode to the collector of IGBT. The increase of saturation voltage will increase the anode potential of the series diode correspondingly,when the set short circuit threshold is exceeded, the protection circuit will operate and turn off IGBT. Since the collector voltage of IGBT is relatively high at the initial stage of opening, if the protection circuit may work at this time, it is necessary to set a blind zone time, during which the short-circuit protection circuit will not work.

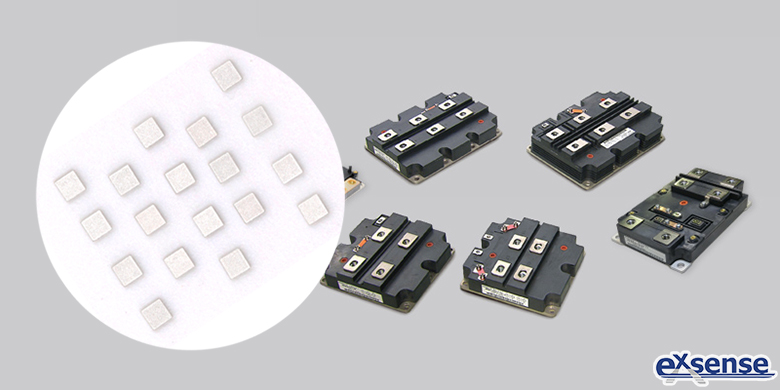

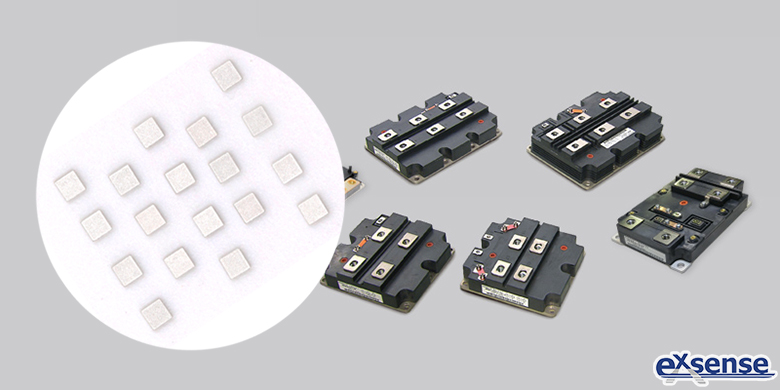

NTC thermistor chip for IGBT produced by EXSENSE Electronics Technology Co., Ltd. decreases its resistance value as the temperature increases. Using this feature, NTC thermistor chip can play the role of temperature monitoring and temperature controlling in IGBT module.