As a compound power semiconductor, IGBT module is being more and more widely used in high power converters because of its low power consumption, high switching frequency and large current capacity, and the requirements for its drive circuit are becoming higher and higher. The main technical development direction is reflected in the following aspects:

First, higher degree of integration

At present, the size of high-power IGBT drive module is relatively large. In order to increase the tolerance of isolation voltage, transformer is usually used to achieve isolation. The size and weight of transformer are relatively large, and it is difficult to achieve integration. Therefore, future drivers will use smaller and more easily integrated isolation devices, such as piezoelectric transformers or advanced magnetic integration technology to reduce the size and weight of isolation elements and increase degree of integration. It can be predicted that the high-power IGBT will be integrated with its drive circuit in the same module in the future, the user only needs to introduce the control signal directly into the power module to realize the control of IGBT.

Second, higher isolation voltage

Photocoupler and transformer are used to realize the isolation of drivers. The advantage of photocoupler is small size, but there are disadvantages such as low isolation voltage, easy aging and large delay. The isolation voltage of transformer to isolate is higher, the delay is smaller, but the size is larger. Therefore, in the occasion which needs high voltage isolation also uses transformer to achieve isolation mostly. At present, IGBT has a maximum voltage level of 6500V, in order to adapt to higher voltage applications, a voltage driver with higher isolation must be used.

Third, higher switching frequency

In order to adapt to the application of induction heating power supply, the switching frequency of IGBT has been increasing. With the development of manufacturing technology, the highest switching frequency of IGBT has been able to reach more than 100Khz, which can partially replace the power MOS tube. For the driver, this means that more drive power must be provided, and the driver must have shorter drive pulse delay time, rise and fall time, provide greater instantaneous maximum drive current, etc..

Fourth, greater drive power

The capacity of IGBT module is increasing, and the current capacity of a single module can reach 3600A. Sometimes, in order to increase the capacity, parallel operation is usually adopted, and the driving power of the driver is also put forward higher requirements. The maximum output current of the driver must be increased accordingly. Especially when multiple modules are connected in parallel, the average output power of the driver must be 5W to 10W, and the maximum instantaneous output current must be more than 30A.

Fifth, more complete functions

The widely used gate drive technology cannot control the DI/DT and DV/DT caused by IGBT switching process, so as to control electro-magnetic Interference (EMI) of conversion circuit. The active gate drive technology can effectively control the higher DI/DT and DV /DT caused by IGBT switch, and correspondingly make IGBT work in a safer working area, reduce the electro-magnetic interference generated during its switching process, and reduce the buffer absorption circuit of IGBT accordingly.

As a key power semiconductor device in power electronic system, IGBT has been growing for several years. Due to it enables power electronic devices and equipment to achieve higher efficiency and higher switching frequency. With the continuous improvement of performance, IGBT has been extended to a wider range of applications, not only in industry, but also in many other power conversion systems, it has replaced the GTR, MOSFET, and even a realistic trend to replace the GTO. The technology of high-power IGBT driver module will be improved continuously, and the degree of integration will be improved, so as to reduce IGBT power consumption and electromagnetic interference, and improve the reliability of the system.

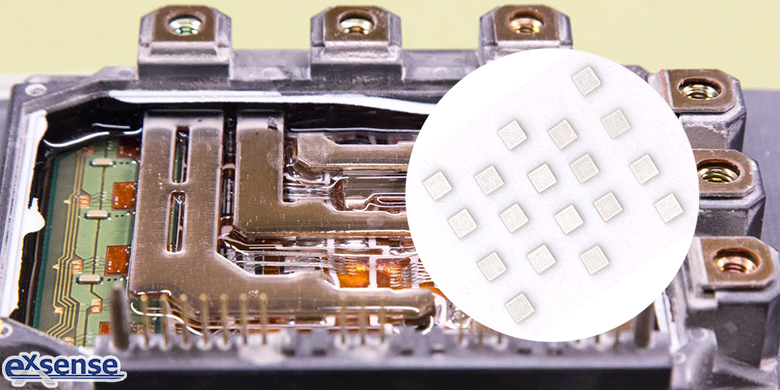

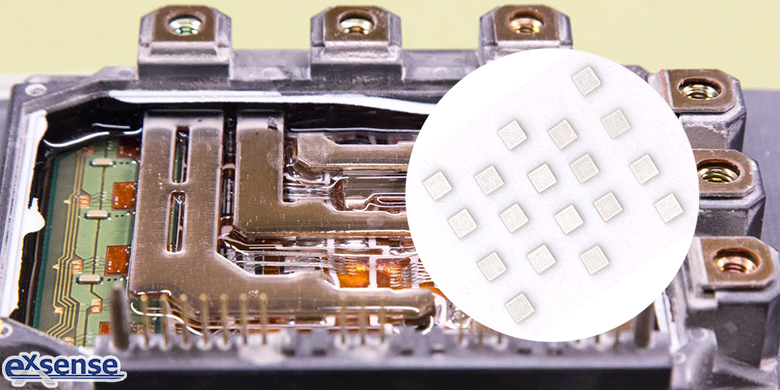

NTC thermistor chip for IGBT produced by EXSENSE Electronics Technology Co., Ltd. adopts advanced semiconductor manufacturing process, combines with independent research and development processing technology, to ensure the high stability and reliability of continuous production of NTC thermistor chip.