With the rapid development of communication field, especially in recent years, the requirement of electromagnetic anti-interference ability of terminal communication equipment is getting higher and higher, which brings great challenges to the design and layout of weak current circuit. Large capacitive reactance and inductive reactance may affect the reliability of communication. In this case, the demand for NTC chip with high reliability, low capacitive reactance, low inductive reactance and not easy to be magnetized is increasing.

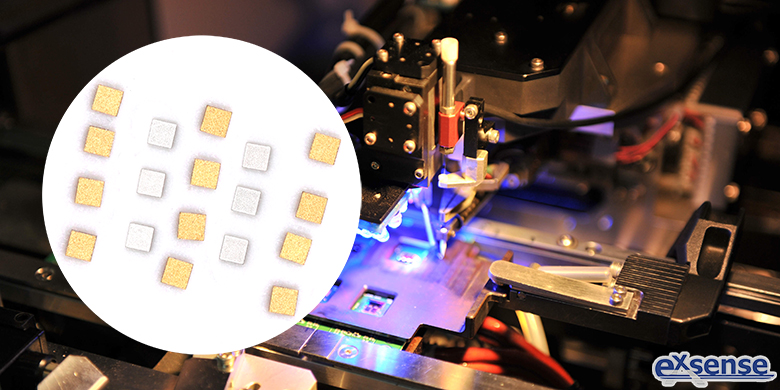

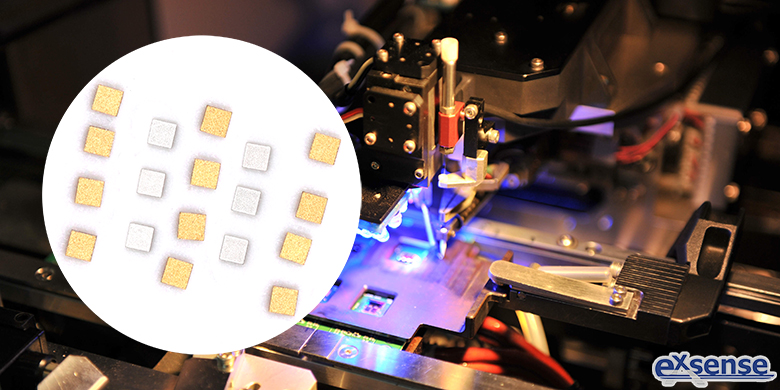

Traditional NTC chip is generally composed of transition elements manganese, cobalt and nickel and iron oxides. As we all know, due to the electron configuration of iron, cobalt and nickel elements, the magnetic properties of these elements are particularly prominent. Thermistor chip materials containing these elements are easy to be magnetize and have high permeability. Thermal materials without iron, cobalt and nickel elements can eliminate this kind of influence, but there is little research on this kind of materials at home and abroad. The negative temperature characteristics of LaMnO3 perovskite structure without iron, cobalt and nickel can be adjusted by the content of Al and Mn to adjust the resistance value and B value of the material, so as to meet the final use requirements. EXSENSE Electronics Technology Co., Ltd. introduces a kind of NTC chip containing almost no Fe, Co, Ni elements, permeability close to 1, which is not easy to be magnetized and it does not conduct magnetism, the specific steps of the preparation method are as follows:

First, with La2O3, MnCO3, Al2O3 as raw materials, according to the molar ratio of La2O3 100, Al2O3 5~50, MnCO3 55~110 placed in the zirconium ball grinding tank, according to weight ratio of raw materials: zirconium ball: water 1:3:2 to add zirconium ball, water, ball grinding for 8 hours, get slurry;

Second, drying the ball-milled slurry at 200℃, calcined at 900~1200℃ for 2~8 hours, get solid powder materials;

Third, put the calcined solid powder material into the zirconium ball grinding tank again, add the zirconium ball and water according to the weight ratio of solid powder material: zirconium ball: water 1:3:1.5, ball grinding for 8 hours, dry 24 hours at 200℃ and press molding; NTC thermistor chip material obtained by sintering at 1100~1500℃ for 5 hours.

This NTC chip is not easy to be magnetized and it does not conduct magnetism, using La2O3, MnCO3, Al2O3 as raw materials, raw materials by zirconium ball grinding, drying, 900~1200℃ calcination, then ball grinding, drying, sintering, get NTC thermistor chip material basically free of Fe, Co, Ni elements. The content of Fe, Co and Ni in the material is less than 0.005%, which solves the problems of traditional thermistor chip containing Fe, Co and Ni materials, easy to magnetize and high permeability. The obtained NTC thermistor chip material is not easy to be magnetized and does not conduct magnetism, the permeability is close to 1. The problem of electromagnetic interference caused by magnetization of NTC chip in weak current circuit is solved.

By controlling the content of Al and Mn, the structure of perovskite can be adjusted. For LaMnO3 with negative temperature characteristics, the molar ratio of La2O3 is 100, Al2O3 is 5~50 and MnCO3 is 55~110, when Al2O3 and MnCO3 exceed the lower limit range, stable perovskite structure cannot be obtained and NTC characteristics are weak, which is not practical. When Al2O3 and MnCO3 exceed the upper limit, stable perovskite structure cannot be obtained, and NTC characteristics is weak and electrical resistivity is high, so it is also not practical.