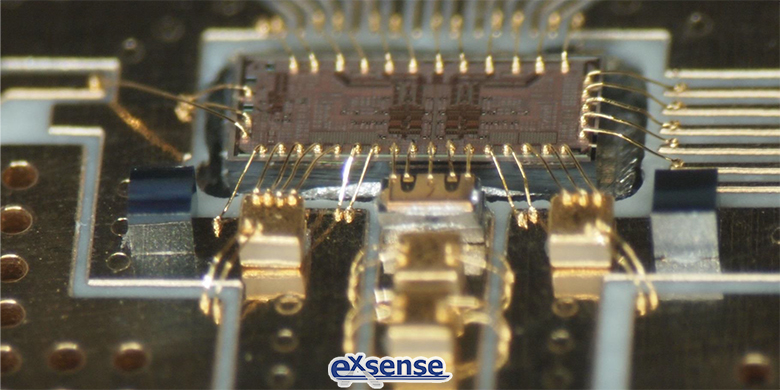

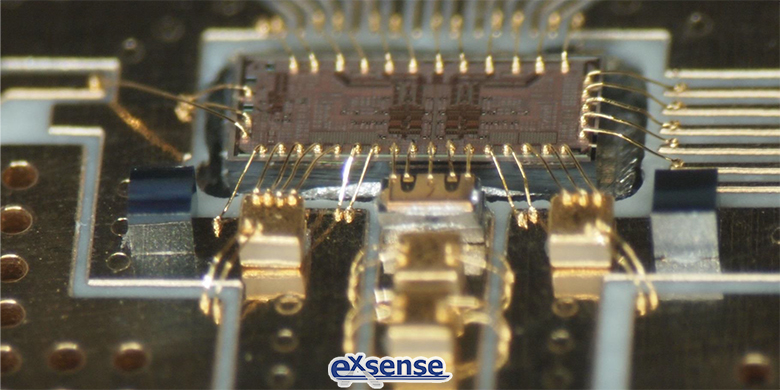

Wire bonding is certainly the oldest and lowest cost interconnect scheme, and the gold has oxidation resistance and high conductivity, which can also be bonded to the specified location through hot compression method and ultrasonic welding technology, so the gold wire bonding process is widely used in the connection of NTC thermistor chip and semiconductor devices external lead.

In a simple wire bonding process, the NTC thermistor chip is first attached to the frame or substrate; The wire is then fed into the tube by a wire bonding machine from a spool in the system, the heat causes the end of the wire to form a small ball; The welding ball is then welded to the welding surface using a welding machine, the system wraps around the wire and then stitches it together; Finally, the molded material covers the wire. Next, EXSENSE Electronics Technology Co., Ltd. will introduce the characteristics of gold and relevant parameters of the gold wire in detail.

The main characteristics of gold

Physical characteristic

1.Electrical conductivity: the resistivity of gold is 2.05μΩ·cm,its electrical conductivity is good, only second to silver and copper;

2.Thermal conductivity: the thermal conductivity of gold is 317W/mK, its thermal conductivity is good, only second to silver and copper;

3.Ductility: Gold has good ductility and is easily manufactured into wire of various sizes. Easy bonding, good wire arc molding.

Chemical characteristic

Gold has stable chemical properties, high corrosion resistance and it is not easy to oxidize at high temperature.

Mechanical characteristic

The stability of wire arc of gold is great and it is not easy to deform after MD.

Gold wire is one of the main bonding wires used in semiconductor encapsulation because of its good ductility, stable chemical properties and great mechanical strength. The selection of gold wire mainly considers the following parameters:

First, purity

According to the purity, gold wire is divided into alloy wire and doping wire. The purity of alloy wire is generally 99% and 99.9%. The doping wire is generally more than 99.99%, and the remaining 0.01% is doped with different proportion and different kinds of trace elements to get gold wires with different hardness or stiffness to adapt to different encapsulating requirements.

Doping palladium, platinum can slow down the growth of IMC, resist the corrosion of bromine, slow down the formation of cavity, and improve the bonding reliability. Beryllium doping can reduce deformation of FAB, facilitate the formation of initial IMC with large coverage, and improve the arc stability and hardness of gold wire. Calcium doping can make use of its high hardness to improve the strength of gold wire. The heat affected zone (HAZ) of rare earth metals is short, and its grains are too small, which can withstand high temperature and high strength. Therefore, doping rare earth metals can make the crystal lattice of sintered balls more symmetrical and FAB more circular, thus improving the radial heat resistance.

Second, breaking load (BL)

The critical value of the force at which the gold wire is stretched to break.

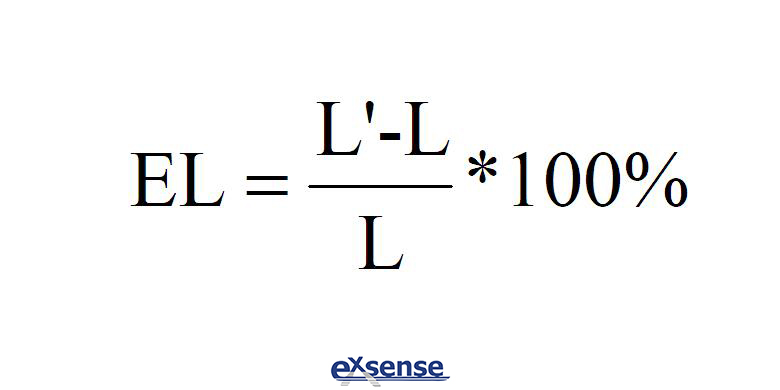

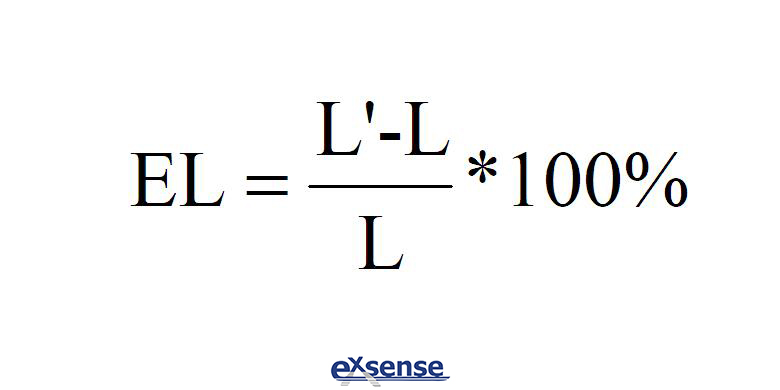

Third, elongation (EL)

The maximum margin that a 0.1m gold wire can stretch is the percentage of the original length.

1.Test method

The 0.1m gold wire is fixed on the fixture, and the fixture is moved at a rate of 10nm/min until the gold wire is pulled off.

2.Formula:

Wherein, L' is the length of the wire after the test and L is the length of the wire before the test.

Fourth, heat affected zone

Heat affected zone refers to the area where the heat after burning the ball affects the grains inside the gold wire. Due to the influence of high temperature, the grain size in this area becomes larger and the hardness decreases by nearly 20% compared with other parts of the gold wire. The length and grain size of this area will affect the shape and strength of the wire arc.

Fifth, wire diameter (WD)

When selecting the diameter of the gold wire, the maximum allowable current, Bonding Pad Opening (BPO) size, loop length and other factors of the product should be considered comprehensively.