The NTC chip for IGBT produced by EXSENSE Electronics Technology Co., Ltd. plays the role of temperature monitoring and temperature controlling in the IGBT module due to its characteristics of high precision, high sensitivity and great reliability. As well as the characteristic of its resistance value with temperature changes, IGBT mould has the advantages of high input impedance of MOSFET and low conductive voltage drop of GTR, the saturation voltage of GTR is reduced, the current density is large, but the driving current is large; The drive power of MOSFET is very small, switching speed is fast, but the on-voltage drop is large, the current density is small. IGBT mould combines the advantages of the above two devices, low driving power and low saturation voltage. Therefore, IGBT mould is very suitable for the converter system which DC voltage is 600V and above, such as AC motor, frequency converter, switching power supply, lighting circuit, traction drive, etc..

During the working process of IGBT module, one of the key parameters to ensure its normal operation is the temperature of IGBT chip. The commonly used method of temperature measurement is to install NTC chip on the IGBT chip as the temperature sensing thermistor chip. In general, NTC chips are installed close to the silicon wafer for tight thermal coupling. Depending on the type of IGBT module, the NTC chip can be also installed on the same DCB as silicon or on a separate substrate.

The internal temperature monitoring of the IGBT module can be carried out in two ways by using the NTC chip:

First, the internal temperature of IGBT module is measured by analog circuit

This method is based on a voltage divider with NTC chip as a thermal device, and the size of voltage divider affects the temperature monitoring and data acquisition of the thermistor chip. If the size is too small, the current flowing inside the NTC chip will cause losses and heat the device, resulting in inaccurate measurements. On the other hand, if the size is too large, the measured voltage will be smaller, which will also lead to the loss of accuracy of the monitoring. In order to reduce the influence of current, the thermal view can be used for detection, so as to avoid failure of IGBT module.

Second, the internal temperature of IGBT module is measured by digital technology

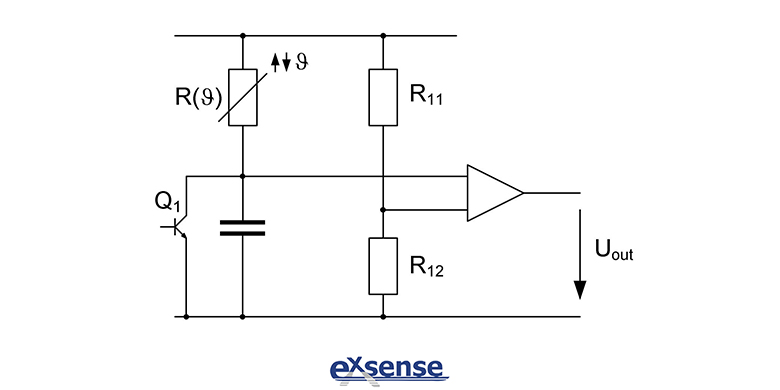

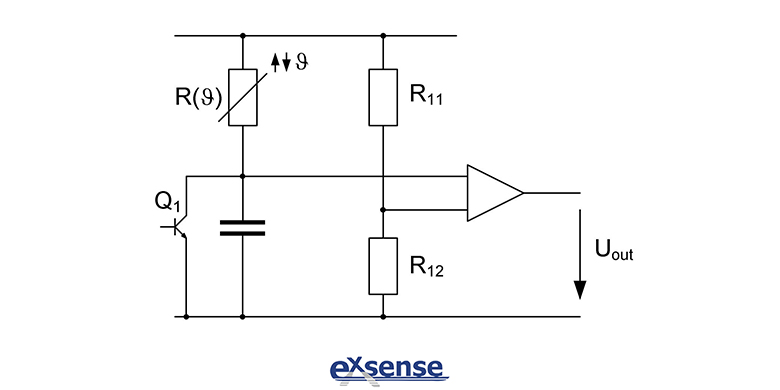

Taking advantage of the characteristic that the resistance value of NTC chip decreases with the increase of temperature and increases otherwise, the time constant of RC component is changed. As shown in the figure below:

Resistors R11 and R12 define the thresholds for the comparator, changing its output. The signal Uout is also used to trigger transistor Q1 to discharge the capacitor. When the charge of the capacitor is defined by the resistance value R (ϑ) of the NTC chip, the Uout becomes a pulse mode with the frequency fout=g (ϑ).

To reconstruct the actual temperature from the Uout, it is sufficient to calculate a pulse over a given period. The number of pulses determines the temperature; Mapping the pulse to the temperature can be described analytically and interpolated between the two closest values.