How NTC Thermistor can Improve Efficiency of Temperature Monitoring in Drive Motor

As the power core of new energy vehicle, the work efficiency and life of drive motor is directly affected by the junction temperature. Abnormal high temperature can easily lead to winding insulation failure, magnet demagnetization, unstable motor performance, and even safety accidents of drive motor. The VT series automotive NTC thermistor produced by EXSENSE Electronics has become key component of the drive motor to solve the above problems due to its sensitive response to temperature changes.

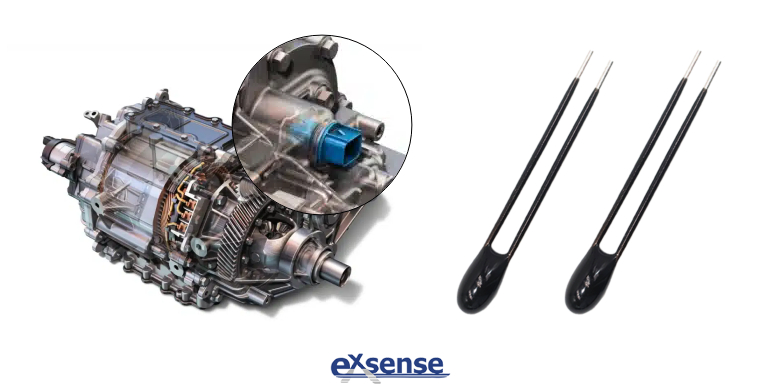

Automotive NTC thermistor is typically placed in the cooling system of the drive motor and is used in the form of temperature sensor for real-time temperature signal acquisition. The temperature signal of the NTC is converted into an electrical signal through the ADC and transmitted to the MCU to realize the dynamic temperature control of the cooling system. Specifically, when the NTC thermistor detects that the junction temperature of the drive motor exceeds the threshold, the cooling system will circulate the coolant or limit the power output of the motor to reduce the operating temperature of the drive motor. In the low-temperature environment, the cooling system activates the preheating mechanism through the temperature signal fed back by the thermistor to improve the operating efficiency of the drive motor. Using the VT series automotive NTC thermistor of EXSENSE Electronics, the drive motor can:

1. According to the real-time temperature data obtained by NTC, the speed of the electronic water pump and the flow rate of the coolant of the cooling system can be effectively and dynamically adjusted, which can respond to the cooling demand more accurately. This helps to improve cooling efficiency and ensures that the drive motor is always in excellent working condition.

2. When the operating junction temperature of the drive motor is within the appropriate temperature range, the cooling system will reduce the regulation of the coolant flow accordingly, so as to achieve the purpose of saving energy and avoiding unnecessary energy consumption.

3. Through the temperature monitoring of the NTC thermistor, the stable working condition of the cooling system can be ensured, so as to prolong the service life of the drive motor and improve the overall working reliability.

The drive motor selects NTC thermistor to realize the closed-loop control of "Temperature Monitoring - Temperature Feedback - Temperature Regulation", which effectively balances its own performance, energy efficiency and safety. The VT series automotive NTC thermistor is highly sensitive to temperature changes, allowing them to capture minute temperature fluctuations and ensure the smooth operation of the drive motor. The high accuracy of this NTC enhances the accuracy of the junction temperature acquisition of the drive motor and reduces the risk of failure caused by abnormal temperature. In addition, the automotive NTC thermistor also has excellent consistency, which can assist the drive motor to better cope with complex environmental temperature changes. With the help of the VT series automotive NTC thermistor, the drive motor can not only achieve early over-temperature warning, but also improve system safety, so that the drive motor can maintain long-term and stable operation.