EXSENSE Electronics Technology Co., Ltd. was established in May 2007 and has been focusing on the research, development and production of NTC chip for IGBT for more than 13 years. With the rapid development of electric automobile in recent years, it has led to the update and iteration of IGBT and other power module encapsulating technology, and also greatly increased the demand of temperature controlled NTC chip.

At present, the main inverter power semiconductor technology of electric automobile represents the advanced level of medium power module technology. However, electric automobile have higher requirements for IGBT-based power semiconductor modules, mainly due to IGBT has high reliability, high power density and high cost performance. The current mainstream of several IGBT modules, mainly divided into the following several:

Discrete device

The design of the discrete device is very classic and clever, single tube of IGBT is clamped on both sides of the cooling channel, three-dimensional design to save space; And facilitate the layout of laminated bus-bar, reduce stray inductance. Its advantages are low cost, high integration, but the design of discrete device is more complex, the thermal resistance is high and the heat dissipation efficiency is low.

1 in 1 module

This is a relatively new form of encapsulating, which adopts the module encapsulating technology, which improves the heat dissipation efficiency and makes the design layout more flexible. However, this technology has relatively higher requirements for the process in mass production.

2 in 1 module

There are two types of 2 in 1 module, the first is the glue encapsulating technology, which is widely used in the early stage and is relatively common in the industry. The second type is plastic sealing technology, which is also the form that the manufacturer with international experience tends to choose. On the one hand, its power density is bigger, which is convenient for miniaturization design; On the other hand, it has a certain cost advantage.

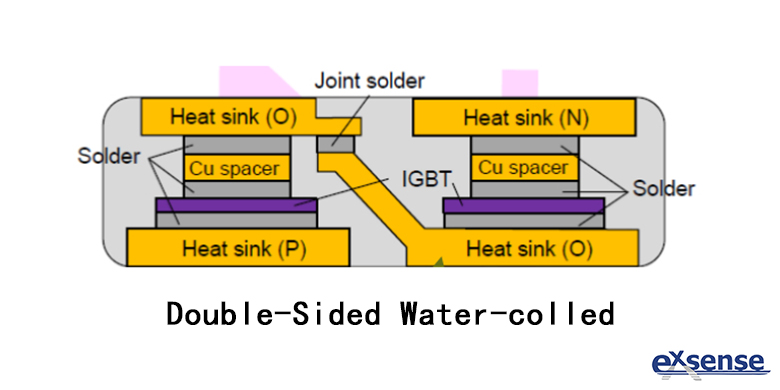

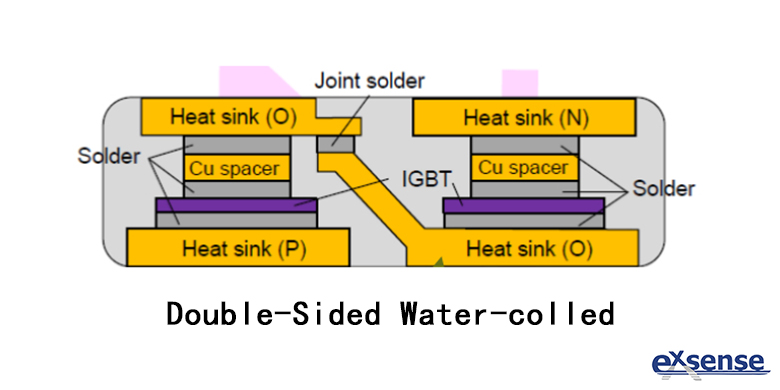

Early use of single-sided indirect water-cooled half-bridge module, the main development direction is double-sided water-cooled and single-sided direct water-cooled. Take the Toyota Prius 4th generation PCU as an example, abandon the previous All-in-1 structure, the use of double-sided water-cooled half-bridge module "plug-in" structure, while the design is clever, greatly improve thermal efficiency, thereby increasing the power density of the system. The module is compact in structure, high in thermal efficiency and high in reliability in plastic sealing, but due to it does not have integrated thermal insulation ceramics, it needs to be designed with an isolation gasket next the radiator.

6 in 1 module

This is currently the most widely used module, especially domestic automotive manufacturers. 6 in 1 module design is relatively simple, the Pin-Fin design significantly improves the cooling efficiency of power modules, increases the power density of modules, and combined with the simplicity of modular design, quickly becomes popular in the automotive industry. Although the 6 in 1 module is simple in design, the power density is high and the application of the threshold is low, the high cost makes it relatively low cost-effective.

According to the current requirements of IGBT module for domestic electric automobile, the 6 in 1 module is not the optimal design for automobile. However, due to its convenience in design and application, it will still occupy the mainstream in the short term. In terms of technology, it will mainly focus on heat dissipation technology and reliability. The advantages of double-sided water-cooled encapsulating technology are, on the one hand, to improve heat dissipation efficiency, and on the other hand, sandwich-type heat dissipation system design is easy to expand. At the same time, compared with silicone sealing module, plastic sealing half-bridge module has a certain mass production cost advantage, and it’s believed that it will become a mainstream direction in the future.