NTC thermistor has the advantages of high sensitivity, low influence by magnetic field, low price, etc., which is widely used in temperature monitoring, temperature control, temperature compensation and other fields. At present, the most practical application of NTC thermistor materials choose Mn-Co-Ni-Cu-Fe spinel-type transition metal oxides, such metal oxides based NTC thermistor material, with its stable performance, a wide using temperature range, has been rapid development, especially manganese-containing spinel-type NTC thermistor material, has become the cornerstone of NTC materials.

Materials based on MnO spinel structures are usually used in the temperature ranges from -60℃ to 300℃. However, the resistivity of MnO material is too high, so it is not applicable as NTC thermal material, the current common practice is to doped with other metal elements to improve its conductivity, nickel is the most widely used element. At present, the vast majority of the spinel-type structure of NTC materials are added to nickel, because nickel ions are not easy to convert into high-valence or low-valence ions, its main role is to enter the B position to form a full-inverse or half-inverse spinal-type crystal structure, prompting the formation of carriers. These NTC materials mainly include Ni-Mn-O, Fe-Ni-Mn-O, Zn-Ni-Mn-O, Co-Ni-Mn-O and Cu-Ni-Mn-O, etc..

However, the addition of nickel has the following disadvantages:

First, nickel is a relatively expensive element, by doping nickel to improve the electrical properties of NTC materials, which will make the material cost higher.

Second, nickel is used in certain devices in contact with the human body, such as bioengineering materials devices, medical equipment, etc., some people will appear allergic phenomenon. As a result, the international use of nickel-containing products is becoming more and more stringent, and even the application of nickel-containing products is prohibited in some industries.

In order to overcome the shortcomings of the above-mentioned existing technology, EXSENSE Electronics introduces a nickel free NTC thermistor, which can effectively reduce production costs and expand product applications. This NTC thermistor, the chemical general formula of its resistance material is CuxZnyMn3-x-yO4, of which 0.1≤ x≤0.9, 0.8≤y≤1, range of B value is 3000 to 5500K, specific resistance at 25℃ is 100 to 60000Ω·CM, the drift rate of resistance is 0.1 to 3%. The preparation method for this NTC thermal material includes the following steps:

(1) According to the structure general formula CuxZnyMn3-x-yO4, of which 0.1≤ x≤0.9, 0.8≤y≤1, the raw materials containing Cu, Zn and Mn were weighed and mixed respectively, after mixing, dispersant and abrasive media are added to make grinding mixing;

(2) Dry the mixed powder, the drying temperature is controlled at 70 to 120℃;

(3) Calcining the dried powder, calcining temperature controlled at 600 to 900℃, calcining time is 1 to 12 hours;

(4) After calcining, binder is added into the powder for granulation to obtain good fluidity;

(5) Press the powder mould obtained in step (4) into shape, molding pressure controlled at 200 to 300MPa;

(6) After molding, the raw material was heated from room temperature to 1000~1200℃ and sintered. The heating rate was controlled at 1~20℃/min. Heat preservated and sintered for 2~24 hours; Then with the furnace cooling to room temperature, the NTC thermistor material is obtained

Wherein, the raw materials containing Cu, Zn and Mn in step (1) are selected from oxides, carbonates, acetate salts or oxalates containing Cu, Zn and Mn; Dispersants include anhydrous ethanol, deionized water, acetone or butanone, and abrasive media include agate balls, zirconia balls or alumina balls; The mass ratio of raw material to dispersant is 1:1~4, the mass ratio of raw material to abrasive material is 1:3~5, the ball milling time is 0.5 to 10 hours, the ball milling speed is 50~200 RPM. The binder in step (4) includes polyvinyl alcohol, polyvinyl butyral or carboxymethyl cellulose. The mass ratio of binder to the calcined powder is 1~5:99~95.

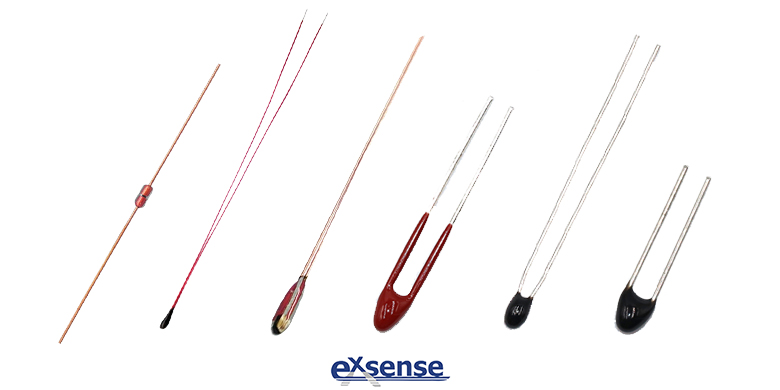

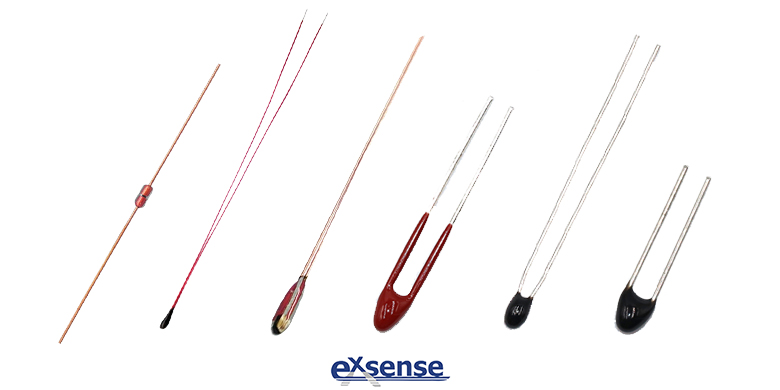

The NTC thermistor produced by EXSENSE Electronics Technology Co., Ltd. is widely used in office supplies, automobile industry, smart home, medical equipment, etc., with the characteristics of good heat resistance circulation, high precision and rapid response, etc..