Manufacturing Method of High-precision and High-reliability NTC Thermistor Chips-1

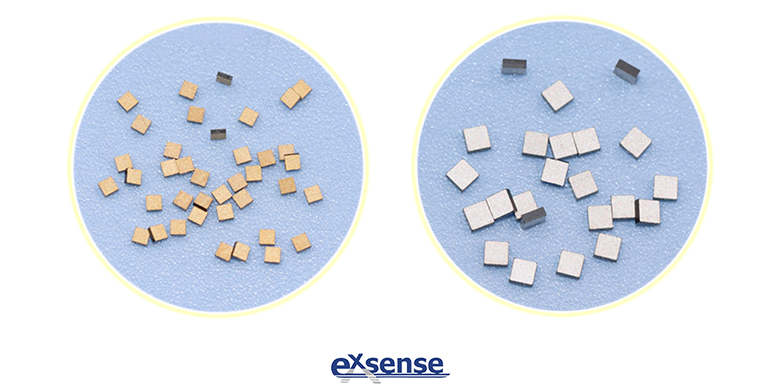

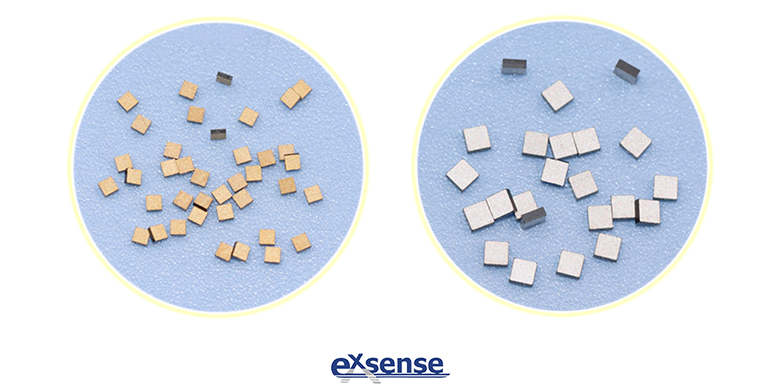

NTC thermistor chips are small size and fast in response, are widely used in bonding and medical treatment, smart home, etc. EXSENSE Electronics Technology Co., Ltd. is adopting advanced semi-conductor processing system, combining with NTC thermistor chip with our own intellectual property rights, using high precision material processing, cutting and testing equipment from Japan, Taiwan and Germany, carry out the high precision mass production of NTC thermistor chip.

In recent years, with the development of science and technology, more and more high requirements are put forward for temperature measurement precision and temperature control precision. Therefore, the NTC thermistor chip is required to have the characteristics of high precision and high reliability. High precision is mainly required that the resistance of NTC thermistor chip and the precision of material constant B value should be controlled within ± 1% and during use, the resistance value and material constant B value changes very small. Reliability is usually described by the the aging characteristics and thermal shock performance of trustworthy test, which requires that the change rate of resistance value ≤ 1% under these two test conditions.

According to domestic and foreign production practices and related literature, the current production of NTC thermistor chips are mainly the following methods:

(1) The use of dry pressure molding + cold isostatic pressure combined to make the billet, after sintering, chips are made by cutting, electrode printing, dicing.

(2) Wet molding is making the material into thin slices, after sintering, the chips are made by electrode printing , dicing. The main wet molding methods are: Scraper film forming method, screen printing method and flow casting method.

In the powder preparation and molding stage, the existing technology either uses the traditional method oxide powder mixed ball milling, pre-sintering, crushing, dry pressure molding, or through a variety of hydrothermal methods into nanoscale powders and then molding. The traditional method requires higher sintering temperature and is difficult to be compact, thus affecting the precision and reliability of resistance values. In addition, another disadvantage of dry pressure molding is that it is easy to have uneven density, resulting in holes, which thus affect and precision and performance. Moreover, all the use of nanoscale powders, will make the production process cumbersome, resulting in high production costs.

The sintering of NTC thermistor billet is usually carried out in the traditional muffle furnace, using the heat conduction method to make gradient heating from outside to inside. First, the sintering time of this heating sintering method is quite long, the production efficiency is low, the energy consumption is high. Secondly, it often causes a significant difference in composition and microstructure between the outer layer and the core of ceramics, it causes the resistance value to change along the radial or longitudinal direction, resulting in a low pass rate of the product.

As a result, in order to improve the precision and reliability of resistance values, now provide a manufacturing method of high-precision, highly-reliable NTC thermistor chip (<Manufacturing method of high-precision and high-reliability NTC thermistor Chips-2>).