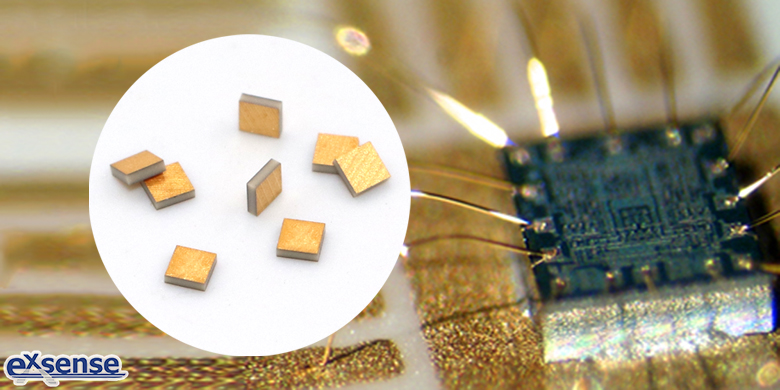

SLC single layer capacitor produced by EXSENSE Electronics Technology Co., Ltd. has the characteristics of small size, solid structure, great frequency characteristics, stable electrical performance and high reliability, etc.. Due to the small size and thin thickness of SLC single layer capacitor, its manufacturing process is difficult. The existing sintering forming process is easy to lead to serious deformation, while the existing cutting process is easy to lead to micro cracks, etc., which is difficult to meet the installation and using reliability requirements of the current single layer capacitor. In order to solve the above problems, EXSENSE Electronics introduces a SLC single layer capacitor, which can effectively solve the flatness problem and micro cracks during cutting of chip capacitor. The specific process steps are as follows:

First, SLC ceramic green blank are obtained by using existing technology;

Second, produce anti-stick powder, which is composed of 60% flour, 30% corn flour, 10% zirconium powder, evenly mixed then obtained anti-stick powder;

Third, the mixed anti-stick powder is evenly adhered to the surface of SLC ceramic green blank, and vertically stacked on the sintered plate, and then pressed on the ceramic plate for sintering. The sintering temperature is from room temperature to 350℃, and the time is controlled at 48 to 54 hours. The sintering temperature from 350℃ to 1100℃ is the rapid heating period, and the time is controlled at 7 to 8 hours. The sintering temperature is kept at the highest temperature for 2 to 2.5 hours.

Fourth, after sintering, SLC ceramic green blank is cooled naturally, and SLC ceramic mature blank can be separated after cleaning;

Fifth, metal electrodes are printed on two surfaces of SLC ceramic blank by vacuum sputtering technology;

Sixth, SLC ceramic mature blank with metal electrodes is clamped between two SLC ceramic mature blanks with adhesive glue, the upper and lower two SLC ceramic mature blanks completely cover the SLC ceramic mature blanks with metal electrodes;

Seventh, cutting, in the cutting process, for the most part of cutting stress is borne by the upper and lower SLC ceramic mature blank, to ensure the cutting edge of middle SLC layer ceramic with metal electrode is smooth. At the same time, the crushing phenomenon caused by the force and the phenomenon that the metal electrode is stripped from the SLC ceramic mature blank when the grinding wheel tool rotates at a high speed are avoided.

Eight, after cutting, clean the adhesive glue and get the SLC single layer capacitor with high flatness.

SLC single layer capacitor with high flatness can effectively solve the deformation problem in the forming process by stacking-sintering SLC ceramic blanks. Through the grinding wheel cutting after the upper and lower clamping, the problems of ceramic easily broken, metal electrode and ceramic separation are effectively solved, and the phenomenon of black spot caused by laser cutting on metal electrode burning is avoided, the flatness and reliability of the product are also improved.