The ever-changing market development trend of the new energy vehicle industry continues to promote the demand for new energy batteries, and also drives the improvement of their cost-effectiveness. At present, in order to broaden the development space and improve the cost performance of the BMS battery management system for new energy vehicles, its temperature monitoring module has gradually transitioned from the traditional wiring harness temperature sensor to the FPC (Flexible Printed Circuit) with SMD type NTC thermistor as the core of temperature measurement, then constitutes a Cell Contacting System (CCS) to help the BMS to carry out intelligent upgrades.

First, compared with traditional wiring harnesses, FPC has a higher degree of integration, which saves costs and improves the overall reliability of BMS; Secondly, FPC has a higher integration density, which not only improves production efficiency of BMS, but also ensures its traceability; In addition, the lightweight structure of FPC is better than that of wiring harnesses, which helps new energy vehicle to achieve energy conservation and emission reduction, extend mileage.

In the traditional solution, BMS battery management system uses the wiring harness NTC for real-time temperature monitoring. Considering that the battery module is composed of multiple battery cells, it is necessary to use multiple sets of temperature measurement wiring harnesses to collect and monitor the temperature, which will not only take up a lot of installation space, but also lead to a complex layout within the battery module. In addition, the wiring harness solution requires a lot of manual operation, which not only accounts for a high proportion of labor costs, but also makes it difficult to set up automated assembly. Therefore, the applications design of FPC can make the temperature measurement process more convenient and space-saving is favored by more and more new energy manufacturers.

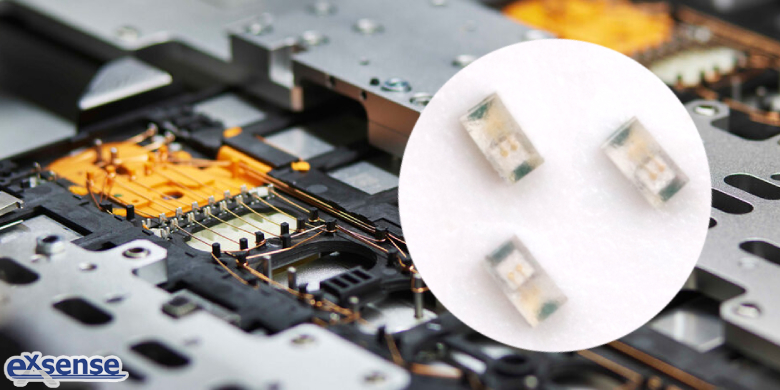

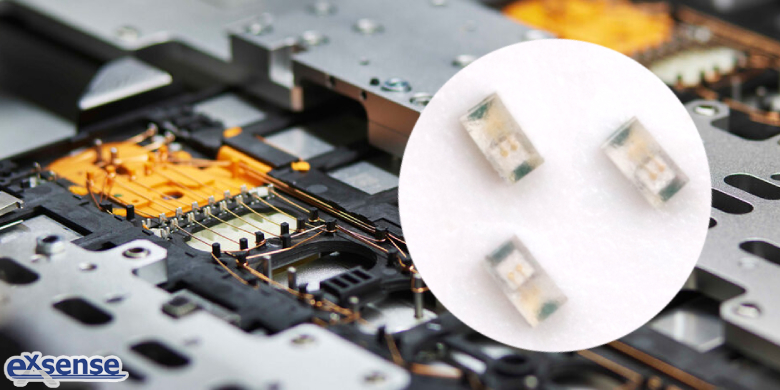

To sum up, in order to help FPC achieve temperature monitoring in battery modules, while moving towards miniaturization, high density, and modularization, most design solutions will choose SMD type NTC thermistor, because of its small size, great thermal cycle resistance, and fast response speed, which meet the selection requirements of temperature measurement NTC for FPC. In order to assist new energy FPC manufacturers to adjust the process and promote the sustainable development of the FPC industry, EXSENSE Electronics Technology Co., Ltd. launched a self-developed and mass-produced CB series high-accuracy SMD type NTC thermistor. Compared with the traditional SMD type NTC thermistor, its bending performance is excellent, the bending limit can reach 10mm, and it can be folded and bent to a certain extent with FPC. And its accuracy can reach ±0.1℃, which effectively improves the accuracy of FPC temperature measurement. CB series SMD type NTC thermistor also because of its SMD structure, which can be closer to the temperature collection point after welding, so that the temperature measurement response is faster.