At present, NTC thermistor and temperature sensor, which take the NTC chip as the core and take different encapsulated forms, are widely used in various medical temperature probes, which play a central role in converting temperature variables into the required electronic signals in the circuit. With the development of electronic technology, all kinds of electronic products gradually tend to multi-functionalization and intellectualization, NTC chip in various needs of temperature detection, temperature control, temperature compensation and other applications are more and more extensive.

Existing NTC chips are generally using the following process: NTC thermosensitive semiconductor ceramic powder prepared-molding-sintering-slicing-terminal electrode printed-dicing-testing. The electrical performance of NTC chips depends on the geometrical size of the product and the effect of the sintering process on the electrical performance of this process in the case that the ceramic powder formulation has been determined. Due to NTC thermosensitive semiconductor ceramic materials are greatly affected by the sintering temperature of the sintering process, the atmosphere of furnace cavity and other conditions, in the process of mass production, the resistance tolerance can only be controlled within 5% generally. Although the sorting of NTC chips can be filtered to meet the needs of high-precision products, but its pass rate is very low, and the thermal impact in lead welding also caused the chip resistance to varying degrees of drift, which makes the pass rate of high-precision products in mass production is very low. In the application of medical temperature probe, the temperature accuracy required can be controlled at 0.5%, which requires the accuracy of resistance value and B value (material constant) can be controlled within 0.3%.

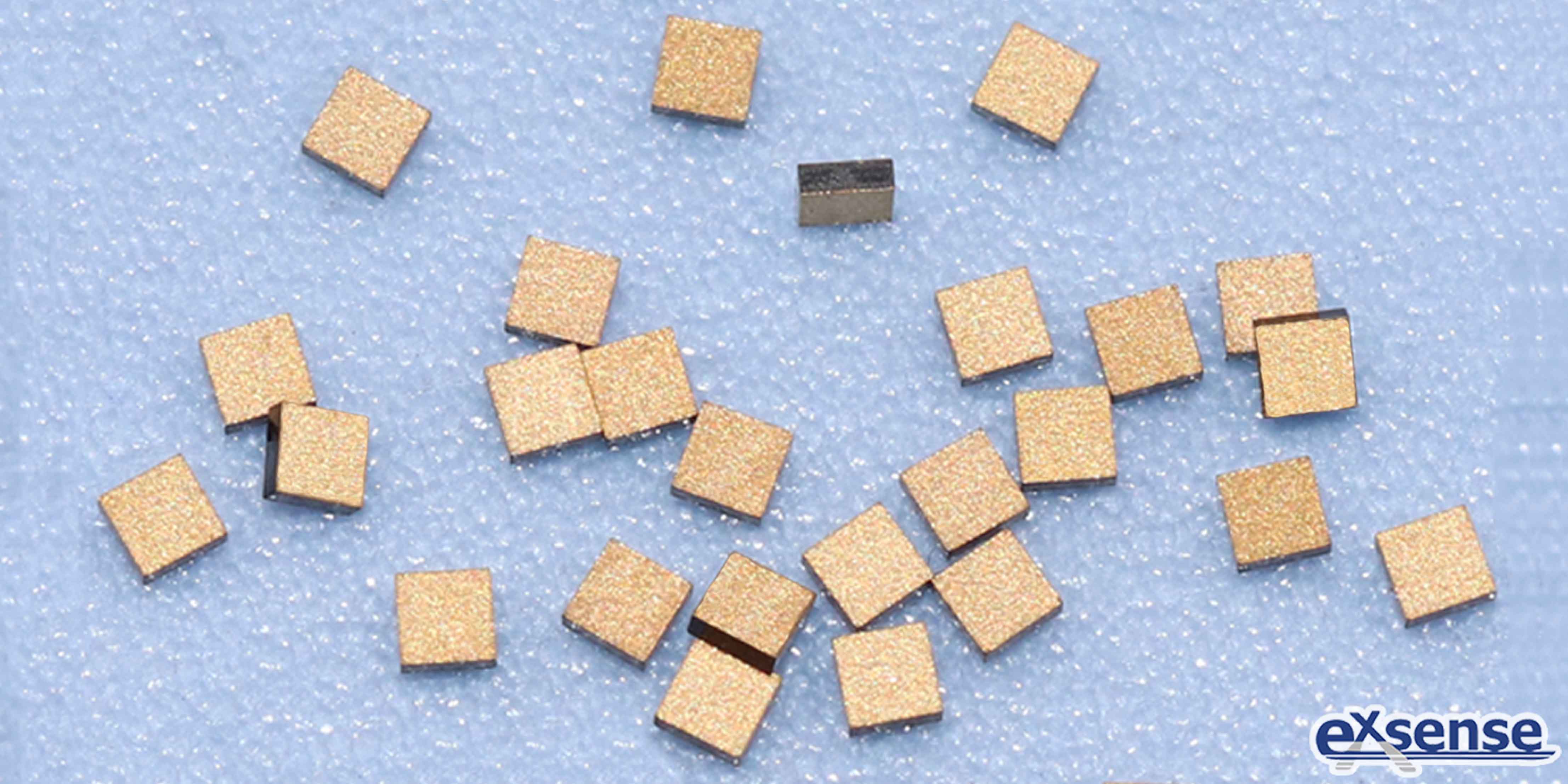

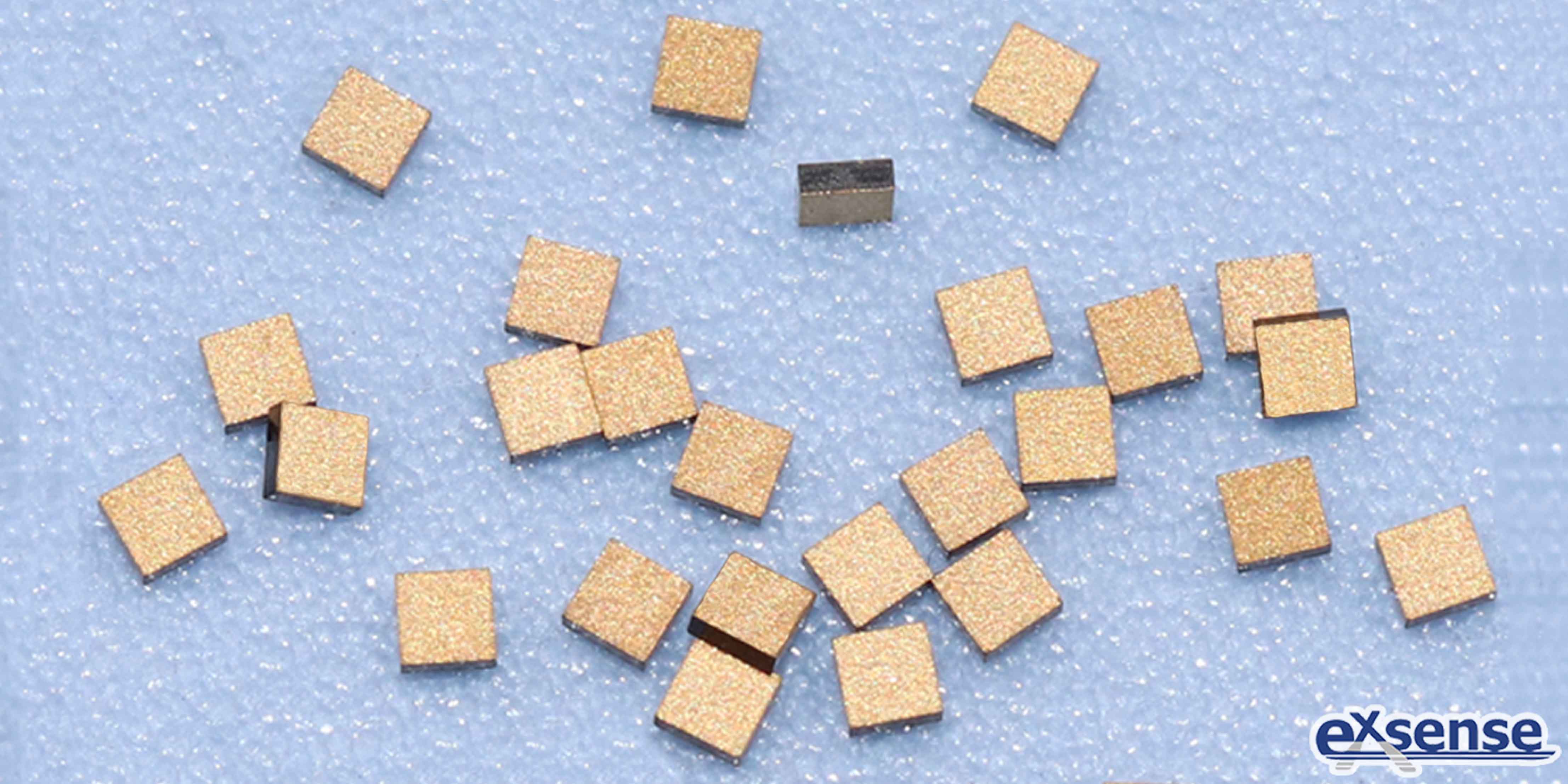

Today, EXSENSE Electronics introduces a high-precision NTC chip for medical temperature probes. With 10KΩ NTC chip as an example, the B value can be controlled at B25/50=3935±0.3% by a specific formulation, and the resistance value can be achieved at high precision of R25=10KΩ±0.3% by adjusting method. In the process of adjusting method, the initial value of NTC chip is small, its resistance value is slowly growing in the process of fine grinding, after that, the resistance value of NTC chip can be controlled at one thousandths, and the pass rate resistance accuracy can be obtained to 90% in the process of mass production, effectively realizing the accurate resistance adjustment of NTC chip. The processes of the resistance adjusting method of this NTC chip is as follows:

(1) NTC thermosensitive semiconductor ceramic powder prepared;

(2) molding, sintering;

(3) Slicing;

(4) Terminal electrode printed;

(5) Silver burnished;

(6) Dicing, chip prepared;

(7) Welding leads;

(8) Aging;

(9) Resistance adjustment, test (R25=10KΩ±0.3%, B25/50=3935±0.3%)

The preparation method of NTC thermosensitive semiconductor ceramic powder in step (1) is ball-milling method.

Isostatic pressing molding method is used in the molding and sintering process in step (2). The prepared NTC thermosensitive ceramic powder placed in the rubber mold, loose, compact by vibration, then placed in the isostatic press, the pressure was released after 30 minutes at a pressured intensity of 300~400Mpa, remove from mold, made ceramic ingots. The pressured ceramic ingots are slowly heated to 1200±50℃ in a high temperature sintering furnace at a rate of 1℃/min, and keep warm for 30 to 50 hours, and then slowly cool down to 100℃ at a rate of 1℃/min, so that high-density ceramic ingots can be obtained.

Step (3) is to use the inner circle cutter to fix the ceramic ingot which after high temperature sintering on the graphite strip with AB glue for slicing, according to the needs of NTC thermistor design, use inner circle cutter cutting the sintered ceramic ingots to the required thickness of 200 to 2000 μm of NTC thermosensitive ceramic substrate.

In step (4), electrode printing is to use silk printing machine to print, using nylon or stainless steel materials to make screen printing plate, its tension is required to be above 10MAP, the number of mesh is 100-200 meshes. Pour the silver slurry of terminal electrode on the screen printing plate and evenly print the silver slurry to the top and bottom sides of the ceramic bar block through silk printing machine. After 100 to 200℃ temperature of the mesh oven baking, get silver slices.

Step (5) is to use the mesh belt furnace to sintering at high temperature. The silver slices with the printed silver electrode was sintered at a high temperature of 800~900℃ so that the silver glass in the silver slurry melted and permeated into the ceramic bar block.

In the dicing, chip preparation of Step (6), the resistivity of silver slices are test, the chip size required to accurately calculate the required resistance value, and according to calculated the size of the resistivity test to cut the slices into pieces precisely, so that a single NTC chip with upper and lower electrodes.

The welding lead process of step (7) is to solder the leads in a high-temperature tin furnace and fix the lead to both ends of the NTC chip electrode to make NTC thermistor.

The aging method of step (8) is to put the welded NTC thermistor in the oven and bake at 90 to 150℃, and keep warm for 50 to 1000 hours.

The resistance adjustment, testing of step (9), the resistance adjusting method is to connect the two leads of the welded NTC chip to the resistance tester, so that the other end of the chip of the NTC thermistor contact the high-speed rotating fine grinding grinding wheel in the oil tank, read the resistance value on the resistance test meter, slowly polish the chip of NTC thermistor, until the desired value is adjusted.

In this NTC chip technology and resistance adjusting method, the initial value of NTC chip is small, and its resistance value is slowly growing in the process of fine grinding. With precision control grinding, NTC thermistor can be controlled at one thousandths, in the process of mass production, 90% pass rate can be obtained with the accuracy of resistance value of ±3%.