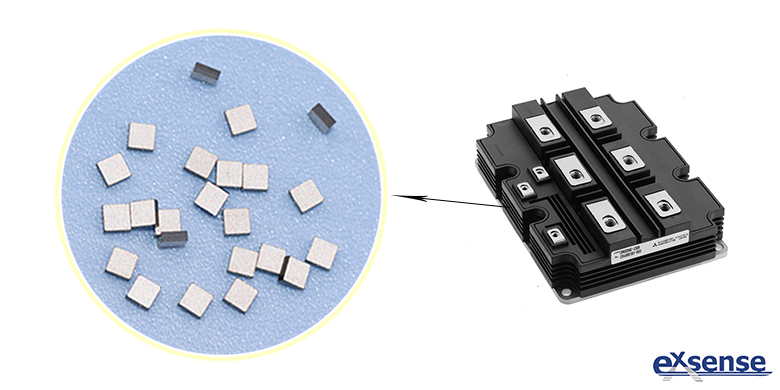

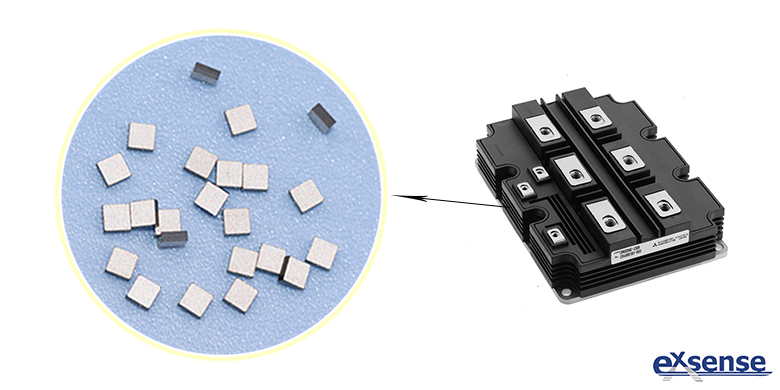

As one of the mainstream components of high power, IGBT, which has the characteristics of small on-resistance, high frequency, thermal stability, energy saving and so on. IGBT is widely used in spaceflight, electric automobile, new energy equipment, consumer electronics, household appliances and other fields. In the working process of IGBT, an NTC thermistor is usually installed for temperature monitoring in order to prevent the operating temperature of the IGBT from being too high and causing accidental damage.

IGBT modules are equipped with an NTC thermistor to monitor the temperature of substrate to facilitate the design of accurate temperature measurements. The thermistor is isolated from the rest of the module using an isolated gel, and most of the heat in the chip flows directly through the substrate to the position of NTC thermistor. Since the heat flow is not transient, the NTC thermistor represents only the temperature of the static operating point. Because the detected relevant time constants are too small, it is not possible to monitor transient phenomena such as heat generated under short-circuit conditions. NTC resistance is exponentially proportional to temperature, so the monitoring circuit must be designed to operate at low power consumption.

Due to the loss of the switch, IGBT will become hotter as the operating length increases. The radiator plate of IGBT is connected to the cooling plate, which is usually water-cooled, and if it is used with impure cooling water or applied low water pressure through the cooling plate, the heat exchange will drop, causing the IGBT to overheat. The NTC thermistor is mounted on the IGBT for effective temperature monitoring, rapid response and feedback to the control interface when the temperature is overheating, allowing the operator to process it in a timely manner and prevent damage to components or machines.

NTC thermistor produced by EXSENSE Electronics Technology Co., Ltd. is made of ceramic technology based on metal oxides such as manganese, cobalt, nickel and copper, etc.. These metal oxide materials have semiconductor properties because they conduct electricity in a way completely similar to germanium, silicon and other semiconductor materials. NTC thermistors have a low number of carriers (electrons and holes) of these oxide materials at low temperatures, so their resistance values are higher; And as the temperature increases, the number of carriers increases, so the resistance value decreases. Therefore, NTC thermistor is widely used in temperature monitoring, temperature control, temperature compensation and so on.

Reference Data:

Monitoring Temperature of IGBT with Embedded NTC Thermistor

Vijit Dubey

Electrical and Computer Engineering

Texas A&M University

College Station, Texas, USA

vijit4072@tamu.edu

[1] V. Rudnev, Handbook of induction heating. New York: Marcel Dekker, 2003.

[2] FF900R12IP4 Datasheet, Infineon Technologies, 2015.

[3] Using the NTC, Infineon Technologies, 2015.

[4] LM555 Timer, 1st ed. Texas Instruments, 2015.

[5] CMOS Counter/Dividers, Texas Instruments, 2015.

[6] Photocoupler, California Eastern Laboratories, 2015.