NTC hermistor, which is made up of NTC thermistor chip as the core, is widely used in temperature detection, temperature compensation and temperature control circuit, which plays the central role of converting temperature variables into the required electronic signals in the circuit. Due to the need of high-accuracy temperature detection and temperature control of electronic equipment, the accuracy and stability of R resistance value and B value of NTC thermistor are more and more demanding.

Existing NTC thermistor chip is produced using the following processes generally:

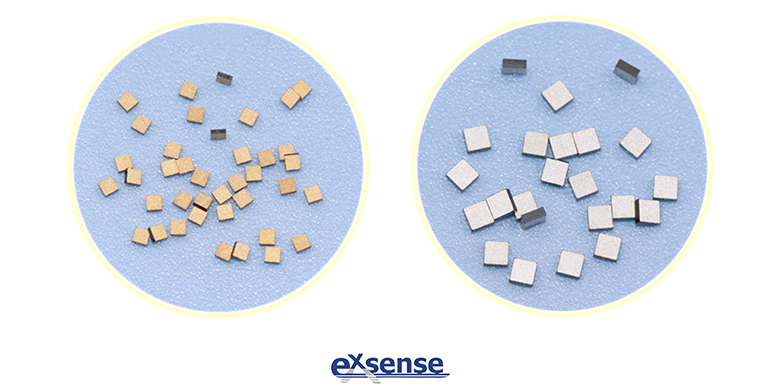

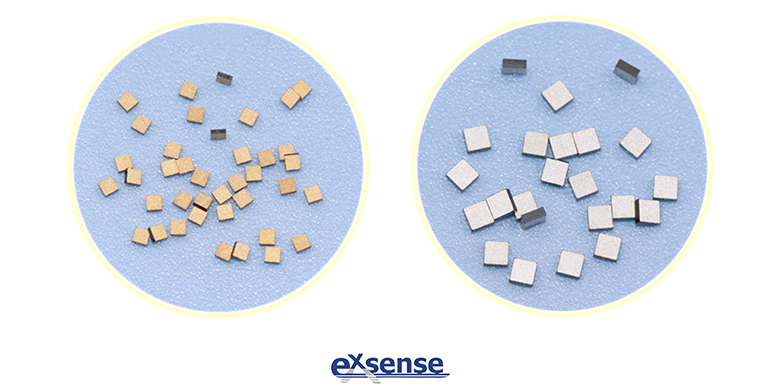

Thermosensitive Semiconductor Ceramic Powder Preparation-- Single Molding-- Sintering-- Electrode Firing and Permeating-- Resistivity Test. This process is made of single NTC thermistor chip from a thermosensitive semiconductor ceramic powder directly, and do electrode firing and permeating at two ends of the thermistor.

This process technology in the case of ceramic powder formulation has been determined, the electrical performance of single NTC thermistor chip depends on the geometrical size of the product and the effect of sintering process on electrical properties. Due to the semiconductor ceramic material is greatly affected by sintering temperature, furnace cavity atmosphere and other conditions of sintering process parameters, there are two obvious shortcomings in the existing manufacturing technology of NTC Thermistor chip:

First, the accuracy of resistance value is low. The electrical properties of the products made of the existing technology are shaped by the sintering process, the resistance value after sintering, electrode firing and permeating of the electrode is dispersed and can not be adjusted, and the accuracy of the R25 resistance in mass production is generally within ±5% and B value(the material constant of the NTC thermistor) within ±3%, which can not meet the high-accuracy requirement.

Second, the stability is poor. After made, the semiconductor ceramic body between the two electrodes of the NTC thermistor chip is exposed, which can easily cause aging between semiconductor ceramics and metal electrodes in the humidity, salt mist, air oxidation, corrosive gas and other harsh environment, thus forming electrical performance drift. The electrical performance drift can up to 3% after 1000 hours of high temperature aging, which goes far beyond the accuracy requirements of the R resistance value and the B value 0.3% required in the application of high precision temperature measurement.

Now, provide a manufacturing method of high-accuracy NTC thermistor chip (high-precision NTC thermistor chip Production-2), which can realize the adjust resistance value in high accuracy well, has high reliability. The NTC thermistor chip produced by this method, the hit rate of high-accuracy product will be greatly improved, the steady state-damp heat property, change rate of high temperature loading and thermal shock of the product are small.