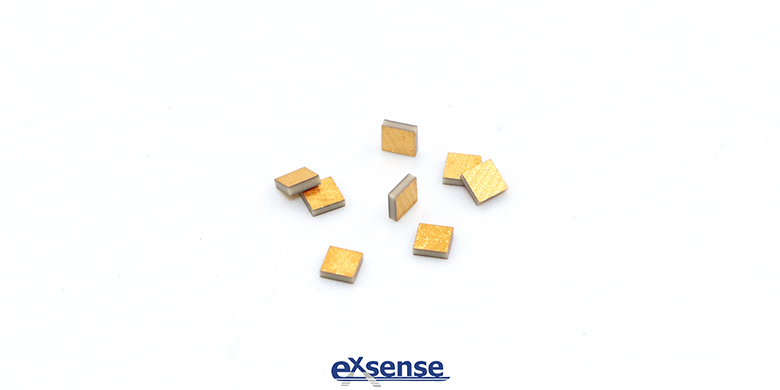

The single layer capacitor produced by EXSENSE Electronics Technology Co., Ltd. has the characteristics of small size, large capacitance and good solderability, which is usually used in microwave integrated circuit with the functions of DC isolating, RF by-pass, filtering and tuning, etc.

This single layer capacitor has good structural strength, which makes the produced process simpler, reduces the costs of production and can utilize thin dielectric layers to provide high capacitance. This chip capacitor for surface mounting, with its high structural strength, green-state ceramic dielectric material and ceramic/metal composite material are laminated together, diced into individual chips, and fired to sinter the ceramic together. The composite material of capacitor comprised an amount of metal sufficient to render the composite conductive whereby the composite may be used for one or both electrodes and for mounting the capacitor to the PC board. Alternatively, the composite material may comprise an amount of metal insufficient to render the composite conductive but Sufficient to act as seed points for an electroplating process wherein the composite is preferentially coated with conductive metal, and the coated composite is mounted to the PC board and the coating provides an electrical connection to an internal electrode, help the surface mounting of chip capacitor.

Single layer capacitor has a very useful form factor for assembly into microwave frequency and similar electrical circuits. These circuits may be laid out on printed circuit boards (PCB), or be present on integrated circuits (ICs) within chip carriers and other packages where space is typically even more precious. The dimensions of the ceramic capacitor can be matched to the width of a strip line on the PC board or the chip carrier holding an IC. In assembly, the bottom face of the ceramic chip capacitor is typically soldered to or conductive epoxy attached to the surface of the PC board substrate. The top face of the ceramic capacitor normally presents one or more electrically conductive pads that are typically ribbon-bonded or wire-bonded to another circuit connection point.

In addition, by assembling the portions of the capacitor in the green state, and co-firing the assembly, a monolithic or essentially monolithic structure is formed having no preformed parts and containing no epoxy, glue, solder, or attachment means within the capacitor body thus further providing high structural integrity for the capacitor and simplifying the manufacturing process while allowing for further miniaturization of capacitors. The green-state method further provides flexibility that allows for a broad range of single laye capacitor values to be obtained as desired by the consumer.

Reference Data:

Inventors: Alan Devoe, La Jolla, CA(US);

Lambert Devoe,San Diego, CA(US);

Hung Trinh, San Diego, (US)

Correspondence Address:

WOODHERRON & EVANS, LLP

2700 CAREW TOWER

441 VINE STREET

CINCINNATI, OH 45202 (US)

Assignee:Presidio Components, Inc.

Appl. N, o.:10/963,231

Filed:Oct.12, 2004

Related U.S. Application Data

Division of application No. 10/694,125, filed on Oct.27, 2003, now Pat. No. 6,822,847, which is a continuation of application No. 10/188,696, filed on Jul.2, 2002, now Pat. No. 6,661,639.

Publication Classification

Int. Cl.7 ......................................... H01G 4/005

S. Cl. ......................................... 361/311