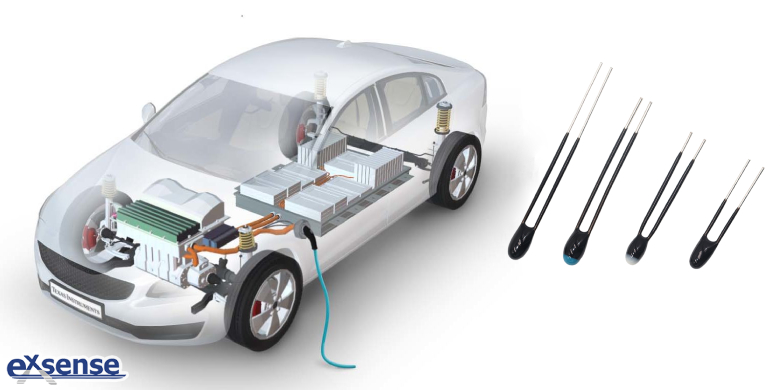

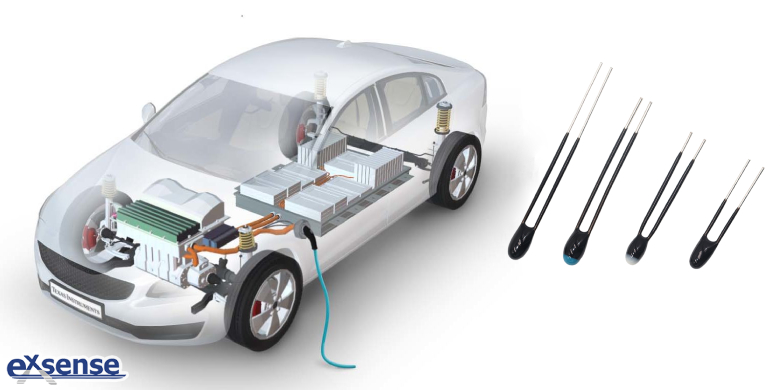

Battery Management System (BMS) is applied to protect automotive batteries from operating outside their temperature, voltage, and current operating ranges. In addition, it monitors the state of charge (SOC), state of health (SOH), and state of power (SOP). Depending on these conditions, BMS uses thermistor to monitor temperature and assist in taking action to protect the system by shutting down, balancing the battery cell, or feeding into the cooling control system.

The chemical properties of car battery is temperature-dependent, if it works outside their thermal range for a long time, they may lead to shortened service life and performance of car batteries. Different battery technologies have unique charge-discharge characteristics and are all affected by temperature. The discharge temperature range is usually wider than the charging temperature range, if the car battery is charged too quickly, it may lead to a shortened life. In addition, prolonged exposure to high temperatures can lead to battery degradation and may lead to thermal runway phenomena and explosions. The low temperature will increase the resistance of the battery, resulting in a significant decrease in charging capacity.

In order to avoid the occurrence of the above problems, BMS designers will choose to insert NTC thermistor in the battery management system to play a role in temperature monitoring and temperature protection. The high-temperature NTC thermistor produced by EXSENSE Electronics Technology Co., Ltd. has the characteristics of great consistency, high precision and simple structure, which has been widely used in the battery management system. BMS designers typically use a voltage divider to bias the NTC thermistor, then the voltage reading of the thermistor is converted to a temperature reading by a Micro-programmed Control Unit (MCU) or Micro Processor Unit (MPU) to actively monitor the battery cell, which can also be used as a switch, on or off the cooling system.

It should be noted that when designing a thermistor temperature monitoring circuit for BMS, the designer must consider tolerance of thermistor, the temperature drift of the bias resistor, the resolution error of the Analog to Digital Converter (ADC), due to these errors will greatly affect the output of the thermistor and are related to system safety. The use of high-temperature NTC thermistor can better facilitate the battery management system to conduct real-time monitoring and fault judgment of the battery pack, effectively preventing the battery from the working situation of overloading.