With the development of electronic technology, NTC chip in a variety of need for temperature detection, temperature control, temperature compensation and other occasions are increasing day by day.

NTC temperature sensor in existing technologies generally include NTC thermistor, filled resin and housing. This NTC temperature sensor has the following disadvantages: Due to the thickness of NTC chip is usually 0.3 to 3mm, and the thickness of outer insulating encapsulated layer (generally is epoxy, phenolic resin, silicon resin) is thicker and thermal conductivity is poor, the filled resin (generally epoxy, phenolic, silicone, heat-conducting silicone grease/glue and other materials) between the housing (generally is metal, plastic, ceramic) and the NTC thermistor, which heat conductivity coefficient is not high, therefore, in the temperature-sensitive process of temperature sensor, heat must pass through several layers to transfer to NTC chip. The heat-conducting property is poor, so that the thermal time constant of temperature sensor is more than 5 to 15 seconds, which can not meet the high sensitivity requirements of temperature detection.

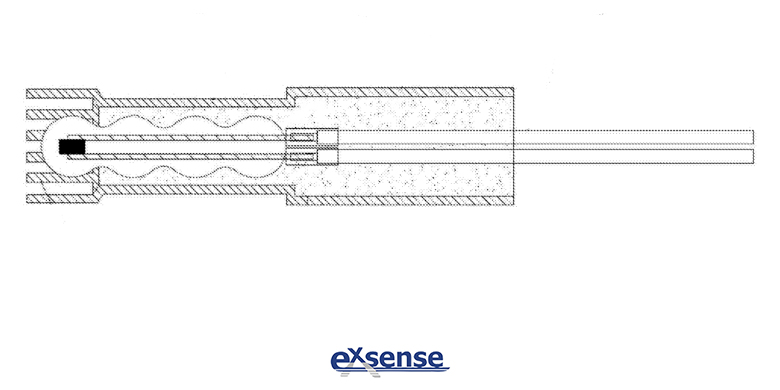

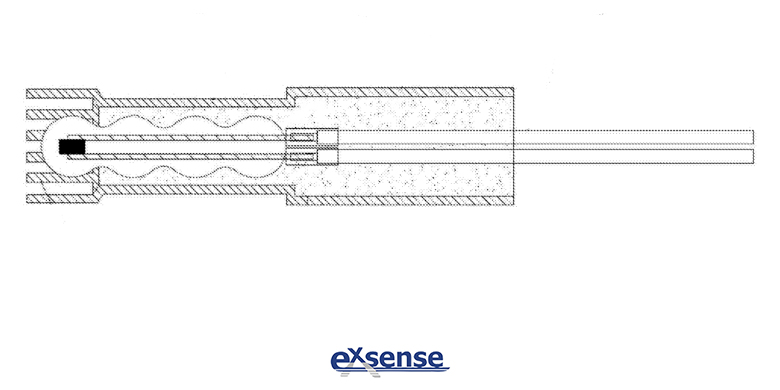

In order to solve the above-mentioned technical problems, EXSENSE Electronics introduces a high-sensitivity fluid temperature sensor with fast reaction speed, high temperature resistance, moisture resistance and high mechanical strength. This high-sensitivity fluid temperature sensor includes NTC thermistor, electronic wires connected to the leads of the thermistor, and housings located outside the thermistor. The NTC thermistor is in glass package, and their glass seal are shape of multi-knot gourd. One end of the housing is a comb-shaped structure, and the end of thermistor with glass seal is fixed in the comb-shaped structure, and exposed to the housing through the comb-shape structure of each comb gap part. The space between the housing and the NTC thermistor is filled with potting compound or injection molding materials.

Compared with the existing process technology, the comb-shape structure of the housing can not only protect the NTC thermistor, but also make one end of the thermistor with a glass seal is partially exposed to the gap between the comb teeth of the comb-shape structure, so that the thermal conductivity of the sensor is higher, the reaction is more sensitive and fast, the response speed is faster, and the resistance to humidity and high temperature is better. The shape of multi-knot structure of NTC thermistor is better combined with the filler, thus improving the water resistance and moisture resistance of the temperature sensor.

NTC thermistor produced by EXSENSE Electronics Technology Co., Ltd., with characteristics of high temperature resistance, high sensitivity, rapid reaction speed, moisture resistance, which can be operated stably in high-temperature and high-humidity environment, to ensure accurate temperature detection.